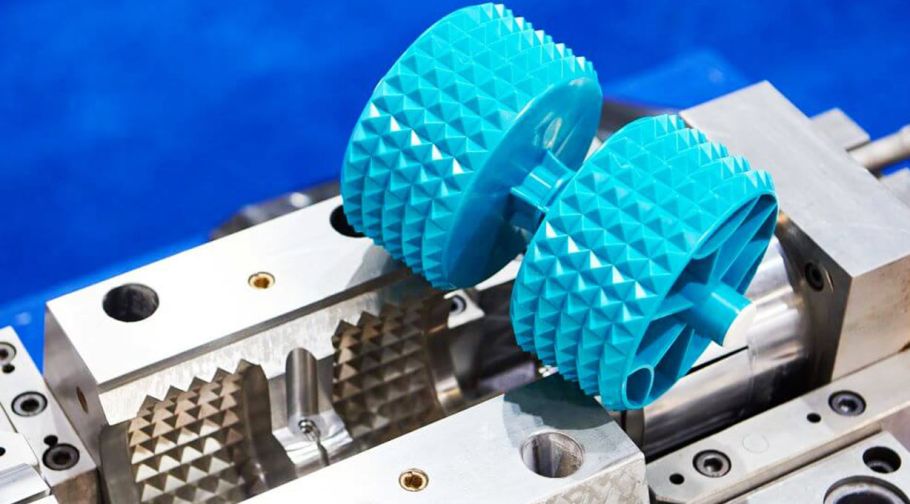

How to effectively control the processing cost of injection molds?

In the process of injection mold processing, many factors such as material selection, mold process design and factory management mode have a crucial impact on processing costs. In order to cope with different application requirements, such as high hardness, high wear resistance or high toughness mold steel selection, we must carefully plan in production engineering to effectively control the processing cost of injection molds. Below, I will elaborate on three aspects.