Capabilities

Mold Design and Analysis

Jinnfeng Plastic unique, molder-friendly approach distinguishes us from the competition. By combining decades of experience with the latest technologies, we deliver the finest tooling available. Our dedication ensures superior workmanship, comprehensive global program management, and advanced product development techniques. Additionally, we offer the industry’s best product lifecycle management system.

By using a data-driven scientific approach to developing and optimizing the injection molding process, we can provide more consistent processing and parts quality for our clients. The Design for Manufacturability, or DFM helps to eliminate costly re-tooling or delays in the manufacturing process caused by a problem within a part design.

We will collaborate with you to thoroughly understand your product design and performance requirements. We will put all of our capabilities to work to ensure that the finished product is exactly what you want it to be, delivering it promptly and precisely as ordered.

Design For Manufacturability

A helpful tool that Jinnfeng Plastic provides makes Injection molded plastic parts just a whole lot easier.

Moldflow Analysis

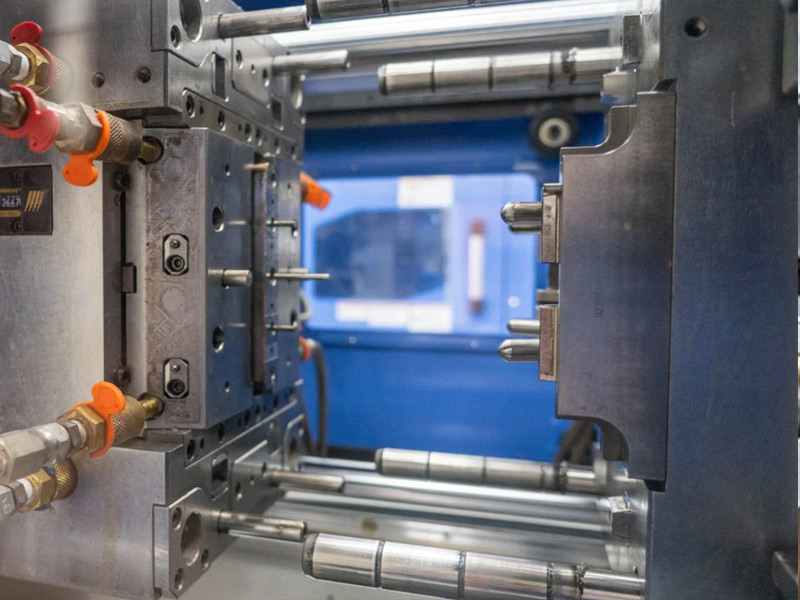

Mold Manufacturing

-

Plate Machining: 48″ wide x 70″ long

-

Mold Handling Weight: Crane capacity to 20,000 lbs.

-

Average molds under construction: 60

-

Annual Mold Production: ~200 molds

-

Normal Design and Build Delivery Time: 11 – 13 weeks.

Manufacturing Problem Solving

-

Experience with a wide range of high-performance specialty materials

-

Modeling using the SOLIDWORKS CAD system

-

Multiple molding methods, including over-molding

-

Deep engineering talent

-

Flexibility, responsiveness, and ability to work within tight schedules

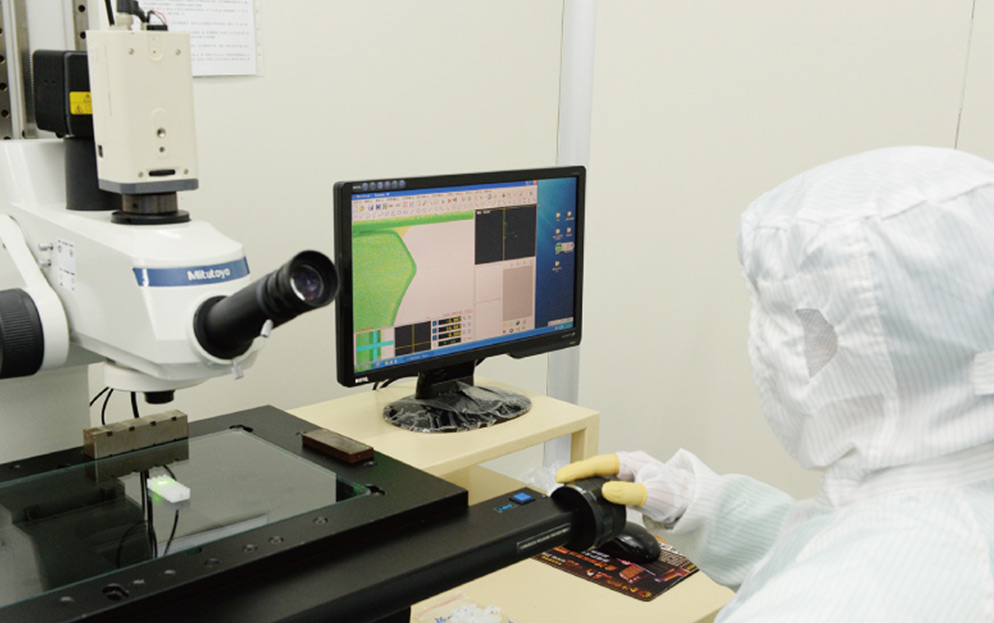

Quality Assurance & Certifications

Testing Equipment

Wear and tensile testing

Constant temperature / humidity testing

3-dimensional image measuring instrument

2-dimensional imager

Certifications & Patents

-

ISO9001 Quality Management Systems (QMS)

-

ISO14001 Environmental management system (EMS)

-

IATF 16949 Automotive Quality Management Systems (QMS)

-

ISO13485 Medical Quality management system (QMS)

-

UL Certification

-

RoHS & Reach Compliant

-

18+ invention patents

Testing Process

-

ISO Quality Standards

-

Dimensional Measurement

-

Material Inspection

-

Durability Test

-

Appearance Inspection

-

Result Record

Industries Served

Consumer Electronics

Automotive

LED Lighting

Energy & Environmental

Computing & Media

Medical

Resource Integration Advantages

-

Die Cutting/Hole Punching/Slitting

-

Laser Etching

-

Precise Assembly

-

Pad Printing

-

Fulfillment and Packaging

-

Shipment to your specified destinations

Rely on Jinnfeng Plastic's One-Stop ODM/OEM Solutions provider, ensuring the seamless execution of your project from inception to delivery.

Technical Capabilities Support

Team Support

Our Team

Management employees: 50+

Sales Team

Engineer Team

Production Team

Injection division: 90+

Molding division: 60+

QA Team

Production Support

Injection Workshop

- 3 standardized workshops with 2 precision-grade workshops + 1 Class 100,000 cleanroom

- 70+ automated injection molding machines: full-range single/double-color processes

High-precision three-coordinate measurement

Japan Mitsubishi wire-cutting machine

Yastar high-speed

Makino precision spark machine