Precision Plastic Mold Development

What's Jinnfeng Plastic's Precision Mold Making Service?

Precision mold is not a novel term. If you consult any mold manufacturer, they will tell you that they specialize in precision mold manufacturing. However, in reality, most molds on the market are not truly precision molds. Limited by factors such as equipment, personnel, and management, most so-called precision molds are merely products executed according to the industry’s standard norms.

At Jinnfeng, we have launched the highest quality precision mold manufacturing services possible, leveraging over twenty years of top-tier mold design experience, the world’s most advanced processing equipment, the industry’s leading factory management system, and a stable and time-tested supply chain system. All these elements lay the foundation for our precision mold services.

From mold flow analysis and mold design to the manufacturing, assembly, and surface treatment of every mold component, we invest a great deal of effort to ensure the precision of the molds and the accuracy of the subsequent injection-molded products. And all of this is accomplished within the set timeframe.

Design For Manufacturing

Jinnfeng Plastic aim to providing the most efficency mold solution to meet our customers molding production demand, through DFM(design for manufacturing) process, we help our customer to optimize their part design to achieve cost wise manufacutirng and make the prefect injection molded parts.

- Wall thickness analysis

- Draft angle,assembly review

- Mold flow analysis

- Injection mold accessories,standard

- General ideas of the injection mold design:

- Parting, runner/gating, cooling, ejection, demolding, etc

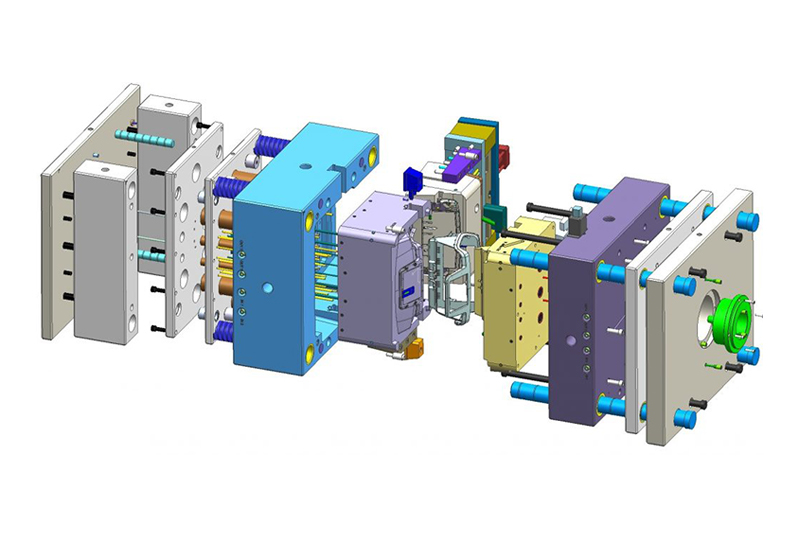

Injection Mold Design

Jinnfeng Plastic design team consist of some of the top mold designers in industrial. We believe high performance molds start with a great design.

- Use UG software for 3D mold design, drawing can be output in STEP, X_T, SOLIDWORKS and IGS format.

- Capability of complex mold structure.

- Familar with HASCO, DME, LKM mold standard.

- End user oriented- design mold for high efficiency production, low maintenance cost.

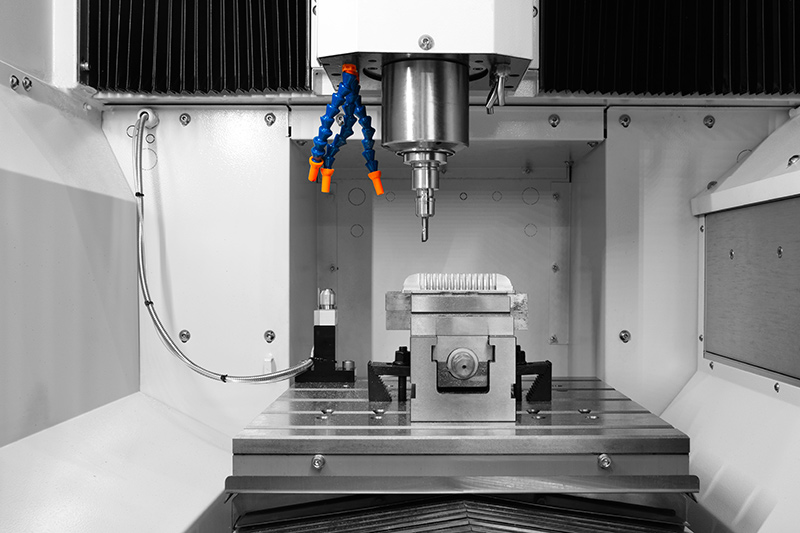

Mold Making

Mold making typically takes 3-7 weeks, depending on complexity, size etc. We are a fully equipped injection mold factory, handling almost all critical mold maching processes in-house, which includes:

- CNC milling

- Grinding

- EDM/WEDM

- Polish/texture

- Mold assembly/fitting

Mold Trial and Sampling

Through mold trial and sampling process, we verify both injection mold and molded parts to ensure they meet our customers’ quality standard in mass production condition.

- Jinnfeng Plastic achieves a 80% success rate at first-time sampling.

- Full shot samples, FAI report

- Videos, injection parameter reports.

- Free for samples submission till approval.

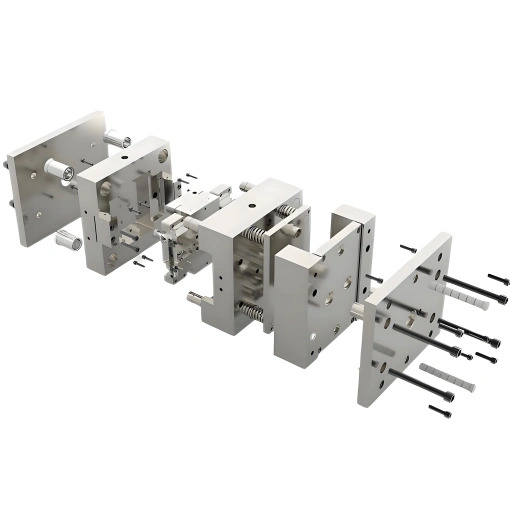

Diverse Array of Mold Structures

Jinnfeng Plastic's high-performance injection molds seamlessly blend craftsmanship with technology. These products, which combine innovation and artistry, are a testament to our dedication and pride.

- Single and multi-cavity molds

- Hot manifolds

- Family molds

- Unscrewing molds

- Over molds

- Prototype mold

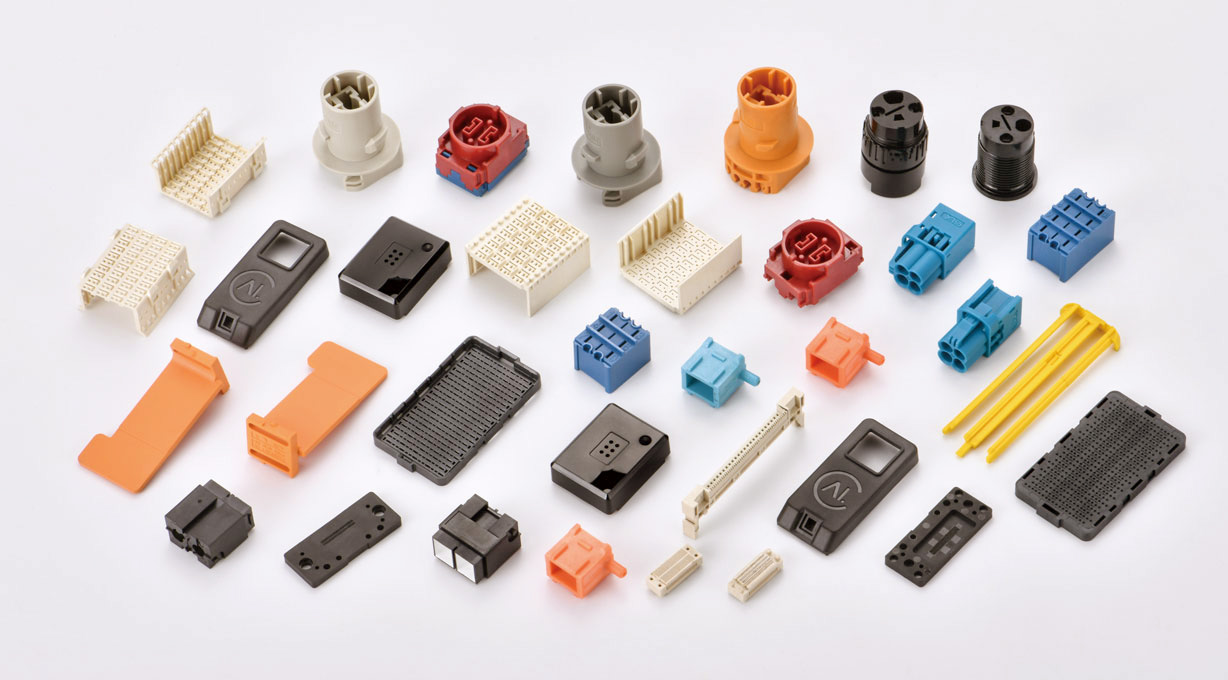

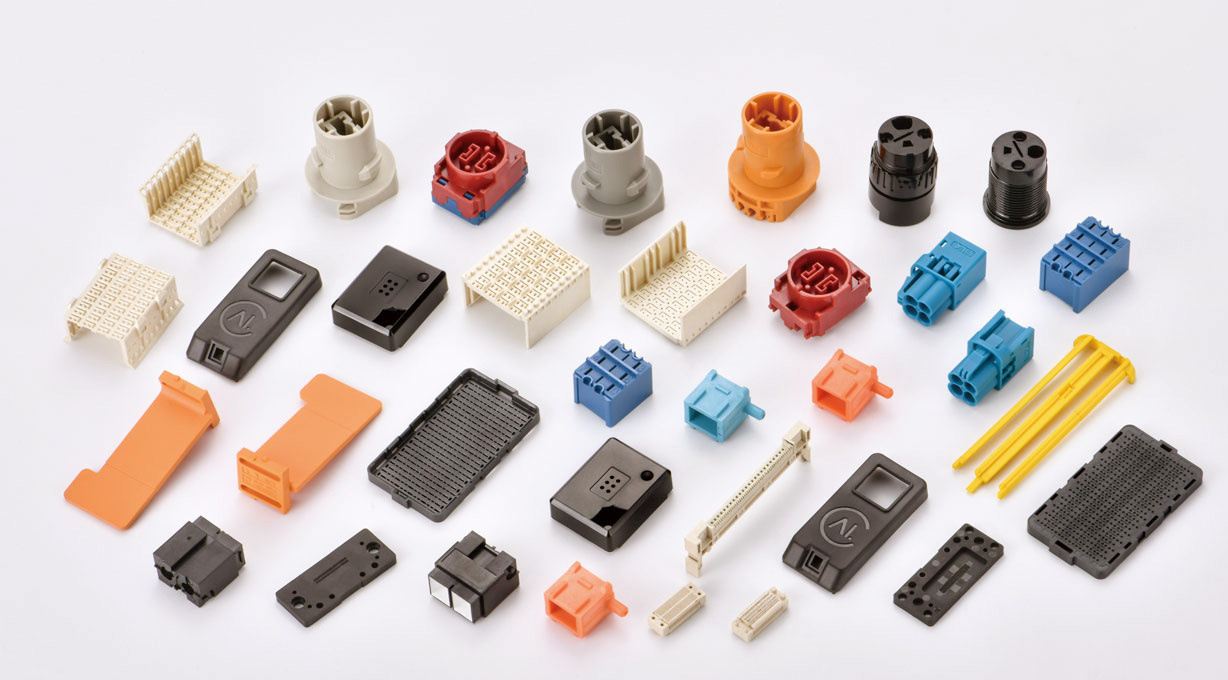

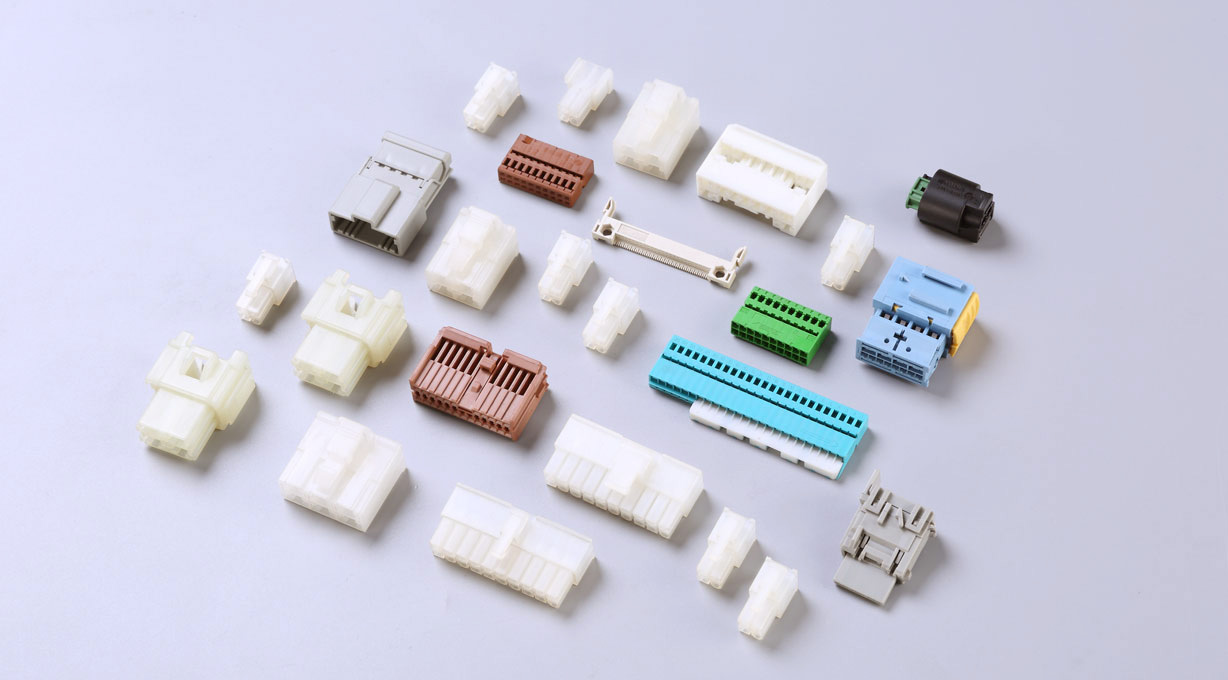

Parts & Products Made By Precision Mold

Precision Plastic Injection Molding is widely used in the medical industry and other high-tech industries, covering various needs from medical devices to medical consumables, as well as injection molding of precision electronic communication products. Each type of mold has its unique design requirements, manufacturing challenges, and application scenarios. Below are several common types of case studies for specialty plastics injection molding processing.

Quality Assurance

The Jinnfeng Plastic design, engineering, and manufacturing teams behind your project are also behind your vision, enhancing your ideas and bringing them to life. It takes years of experience to build the kind of expertise we can offer in engineering and manufacturing services which is why we have successfully serviced large customers and global industry leaders.

Thanks to our highly vetted supplier network and ISO 9001-certified Quality Management System, it’s always possible to have your parts manufactured with industry-specific certifications. Our manufacturing partner network can certify to the following standards: ISO 14001:2015, IATF 16949:2016, ISO 13485:2016 and ISO 9001:2015.

UL Certification

RoHS Compliant

Reach Compliant

Industry Applications

Our areas of expertise include: precision injection molding, medical injection molding, tungsten steel part processing, and injection molding production of special plastics such as PEEK, LCP, PEI, PPS, PPSU, PFA, etc. The company is certified to ISO9001, ISO14001, ISO/IATF16949, and ISO13485 medical system standards. Over the years, with excellent quality, delivery, and service, we have earned the trust of customers both domestically and internationally, becoming a key partner for many international large-scale enterprises in various fields, including automotive engineering, electronic and electrical engineering, aerospace, medical technology, tooling fixtures, and machinery equipment manufacturing.

Consumer Electronics Precision Parts Solutions

Automotive Injection Molding Components Solution

LED Lighting injection mold components Solution

Energy & Environmental injection mold components Solution

Computing & Media injection mold components Solution