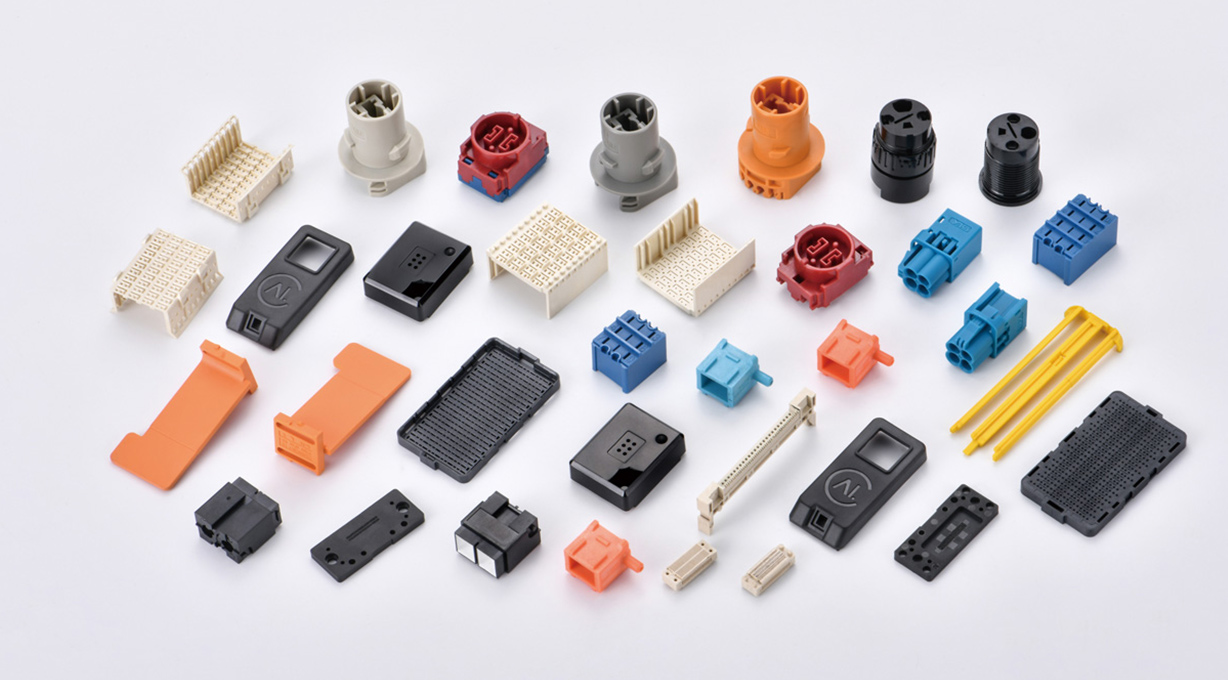

Automotive Injection Molding Components Solution

Solution Introduction

Jinnfeng Plastic has been dedicated to the processing and production of high-end precision connector products, forming a complete OEM system that spans from mold design, mold components, precision molds, to injection molding processing. The design, material selection, and production process of automotive injection molding components are key to ensuring the functionality, reliability, and quality of the components. Precision injection-molded small parts are extensively used in automobiles, covering various fields from electronic systems, interior and exterior trim, to functional components.

Currently, Jinnfeng Plastic holds the IS016949 automotive component manufacturing qualification, capable of injection molding a variety of precision injection-molded products, including those made of PEEK, LCP, PPSU, PPS, PEI, PBT, and other materials.

Solution Values

Clear Division of Labor

Environmental Improvement

Supply Chain Management

Processing Steps

Inquiry evaluation

Design drawing

Sample preparation

Mass production

Order delivery

After-sales service

Application Cases

Automotive Connectors

Automotive Communication Connectors

Competitive Advantages