Quality Assurance & Certifications

Continued improvement as an integral part of our corporate culture.

High quality is our top priority

Our Quality Policy reflects this mindset, anchored in our commitment to delivering excellence.

We strive for excellence in manufacturing. Every part produced through our network meets the highest standards and we’re constantly raising that benchmark. We never settle when it comes to quality and we design our quality management systems so we never have to.

In order to meet the Quality objectives and comply with the Policy, Jinnfeng Plastic’s management is committed to:

- Working in partnership with its customer base

- Supplying quality products that satisfy customer expectations, at a competitive price, in a timely manner

- Offering efficient, courteous, and personalized customer service

- Fostering team spirit among our employees

- Investing in the technological development of our products

- Ensuring continued delivery of the Quality Policy through sufficient resources

- Conducting management reviews to maintain the efficiency of the Quality System

IATF/ISO Certifications

Thanks to our highly vetted supplier network and ISO 9001-certified Quality Management System, it’s always possible to have your parts manufactured with industry-specific certifications. Our manufacturing partner network can certify to the following standards: ISO 14001:2015,

IATF 16949:2016, ISO 13485:2016, ISO 9001:2015, UL Certification, RoHS & Reach Compliant.

Testing Equipment

Thanks to our highly vetted supplier network and ISO 9001-certified Quality Management System, it’s always possible to have your parts manufactured with industry-specific certifications. Our manufacturing partner network can certify to the following standards: ISO 14001:2015,

IATF 16949:2016, ISO 13485:2016 and ISO 9001:2015.

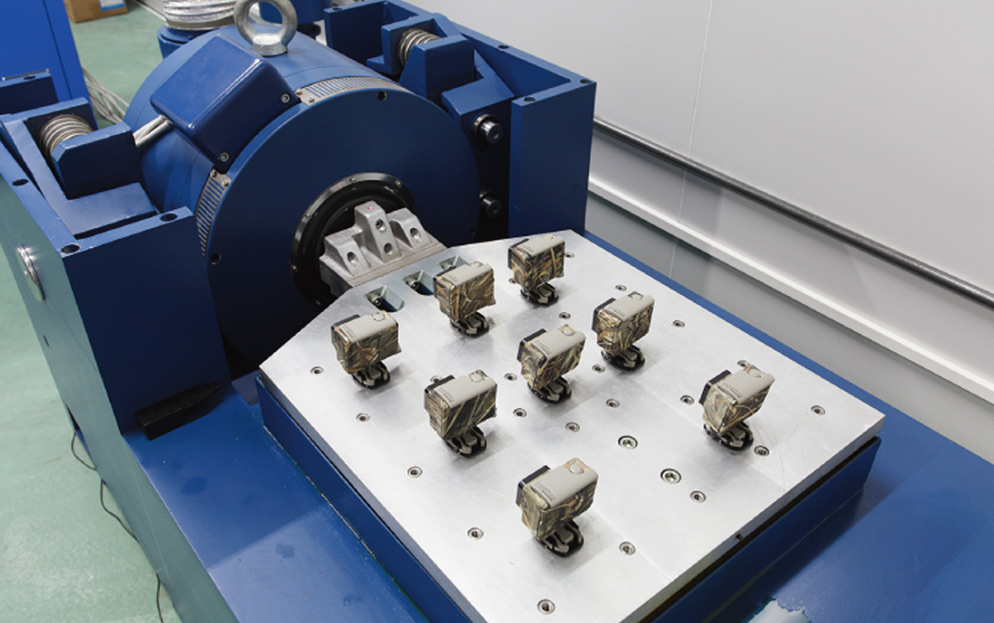

Wear and tensile testing

Constant temperature / humidity testing

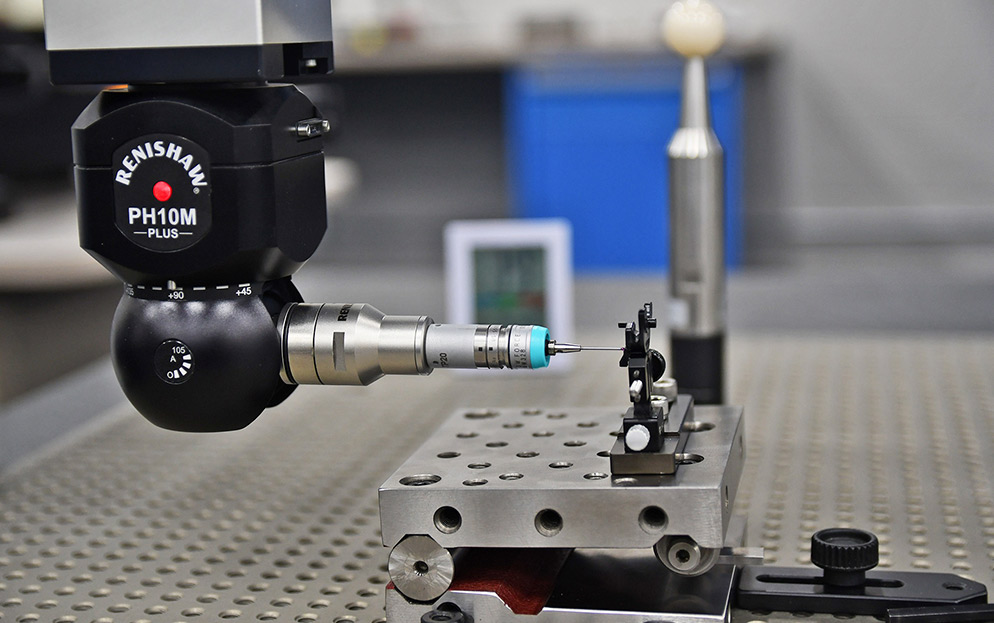

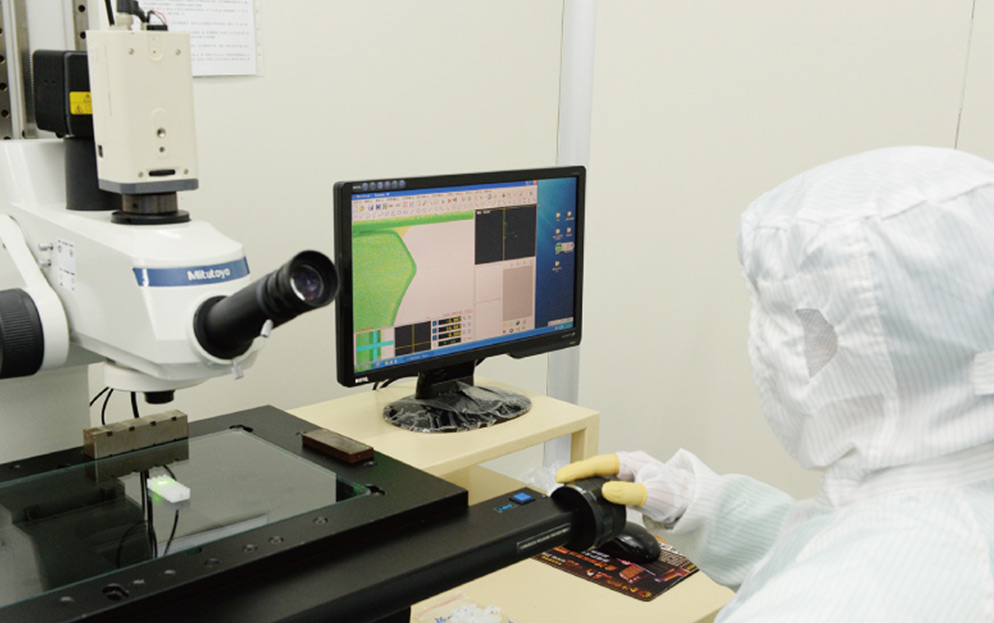

3-dimensional image measuring instrument

2-dimensional imager

Testing Process

Before the injection molding of a new mold or when the machine is replaced with other molds, the mold testing is an indispensable part. The test results will directly affect whether the follow-up production of the factory is smooth. Therefore, reasonable operation steps must be followed and the useful technical parameters recorded in the mold testing process in order to facilitate the mass production of the product.