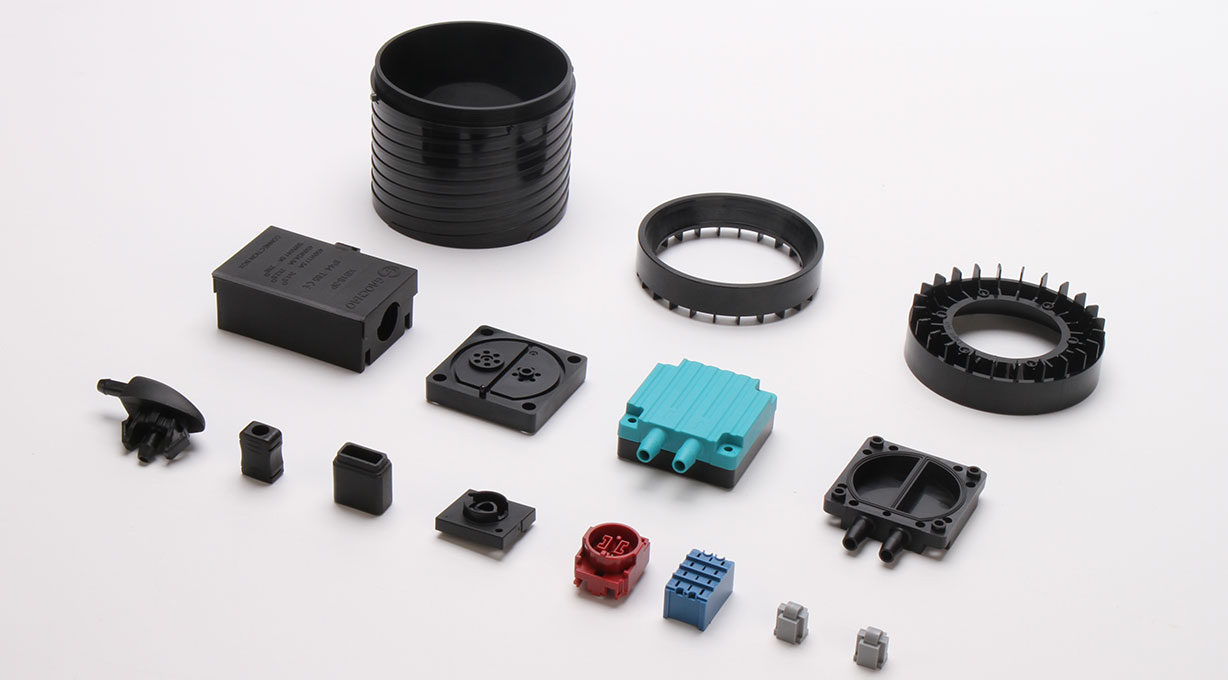

Consumer Electronics Precision Parts Solutions

Solution Introduction

3C Electronic Precision Injection Molded Parts refer to precision injection-molded components used in consumer electronics, communication devices, computers, and other products. Injection molding technology is widely used for mass production of small, complex, and intricate plastic parts, especially in 3C products, where these components often need to have high precision, high strength, and good surface quality. Precision injection-molded parts play a crucial role in 3C products such as mobile phones, tablets, home appliances, and smart hardware.

Solution Values

High Precision and Complexity

Using precision molds and advanced injection molding technology, complex parts with very small dimensional tolerances can be manufactured, with common tolerances reaching ±0.1mm or even less.

Miniaturization and High Integration

As 3C electronic products continue to develop towards smaller and lighter designs, precision injection-molded parts often need to be miniaturized and have higher integration during design, such as integrating multiple functions into a single component.

High Strength and Durability

Processing Steps

Inquiry evaluation

Design drawing

Sample preparation

Mass production

Order delivery

After-sales service

Application Cases

Precision Camera Components

Precision PBT Material Parts

Competitive Advantages