Surface Treatment

One-stop surface treatment supporting our main processes

At Jinnfeng Plastic, our core business revolves around the manufacturing and processing of plastic and metal parts. To provide a seamless experience for our clients, we offer a comprehensive range of surface finishing services that ensure your products benefit from an all-in-one solution—from manufacturing to surface finishing to assembly.

A portion of these surface finishing processes, such as screen printing, laser engraving, and spray painting, are handled by our in-house team. For other surface finishing techniques, we rely on our long-term partners who have proven to offer the most reasonable craftsmanship and pricing.

By choosing Jinnfeng Plastic, you can rest assured that your products will receive high-quality, efficient, and cost-effective surface finishing services.

Laser Engraving

Laser engraving is a surface treatment process that utilizes laser technology to engrave patterns, text, or images. This technique employs a laser beam to carve designs and can be applied to various materials, including wood, glass, metal, and plastic. The function of laser engraving is similar to that of screen printing and pad printing.

Laser engraving is a very common and straightforward printing process with highly mature technology. Most mold factories or CNC machining factories are equipped with this surface treatment process. FirstMold has six laser engraving machines dedicated to providing engraving services for injection-molded parts, CNC machined parts, and 3D printed parts, including text, logos, and patterns.

Screen Printing

Plastic products after injection molding often require various patterns or texts to be printed on the surface. This calls for the use of various printing techniques for surface treatment of the parts. Common printing techniques include screen printing, pad printing, lettering, and laser engraving. Today, we’ll delve into the mysteries of screen printing.

Screen printing is a relatively simple technique and therefore is the most commonly used surface treatment technique for plastic parts. Some injection molding factories handle this surface treatment themselves, and FirstMold is one of them.

Screen printing is the abbreviation of “silk screen printing.” The screen printing technique utilizes a mesh screen to transfer ink onto a substrate(fabric, paper, plastic, or metal), in specific areas to create the desired design or pattern.

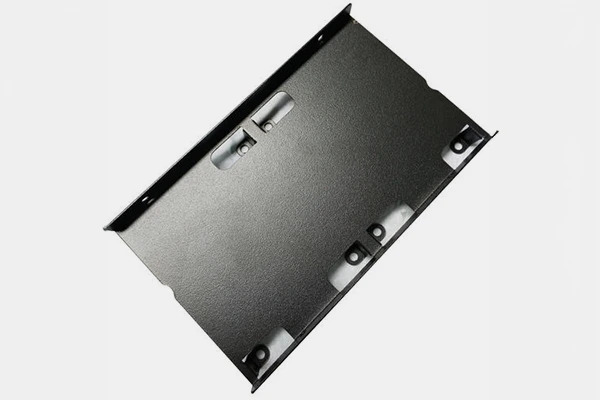

Spraying

Spraying is an extremely common surface treatment process for parts. It mainly involves using a spray gun or a disc atomizer, utilizing pressure or centrifugal force to disperse the coating into uniform and fine droplets, which are then applied to the surface of the object being coated. The spraying surface treatment process is suitable for different materials such as metal and plastic.

Spraying is a general term for a surface treatment process. It further subdivides into various types.

Electroplating

Electroplating is one of the most common surface treatment processes for parts, applicable to both metals and plastics. Electroplating involves placing the metal to be plated as the cathode in a solution containing the desired plating metal, with the plating metal or another inert conductor as the anode. Through electrolysis under direct current, a firmly bonded metal film is formed on the surface of the substrate.

The purpose of electroplating is to enhance the appearance of the material while imparting various physical and chemical properties to the surface, such as corrosion resistance, decorative quality, wear resistance, solderability, and electrical, magnetic, and optical properties.

Quality Assurance

The Jinnfeng Plastic design, engineering, and manufacturing teams behind your project are also behind your vision, enhancing your ideas and bringing them to life. It takes years of experience to build the kind of expertise we can offer in engineering and manufacturing services which is why we have successfully serviced large customers and global industry leaders.

Thanks to our highly vetted supplier network and ISO 9001-certified Quality Management System, it’s always possible to have your parts manufactured with industry-specific certifications. Our manufacturing partner network can certify to the following standards: ISO 14001:2015, IATF 16949:2016, ISO 13485:2016 and ISO 9001:2015.

UL Certification

RoHS Compliant

Reach Compliant

Industry Applications

Our areas of expertise include: precision injection molding, medical injection molding, tungsten steel part processing, and injection molding production of special plastics such as PEEK, LCP, PEI, PPS, PPSU, PFA, etc. The company is certified to ISO9001, ISO14001, ISO/IATF16949, and ISO13485 medical system standards. Over the years, with excellent quality, delivery, and service, we have earned the trust of customers both domestically and internationally, becoming a key partner for many international large-scale enterprises in various fields, including automotive engineering, electronic and electrical engineering, aerospace, medical technology, tooling fixtures, and machinery equipment manufacturing.

Consumer Electronics Precision Parts Solutions

Automotive Injection Molding Components Solution

LED Lighting injection mold components Solution

Energy & Environmental injection mold components Solution

Computing & Media injection mold components Solution